-

Call Us

-

Email Us

Call Us

Email Us

Table Of Content

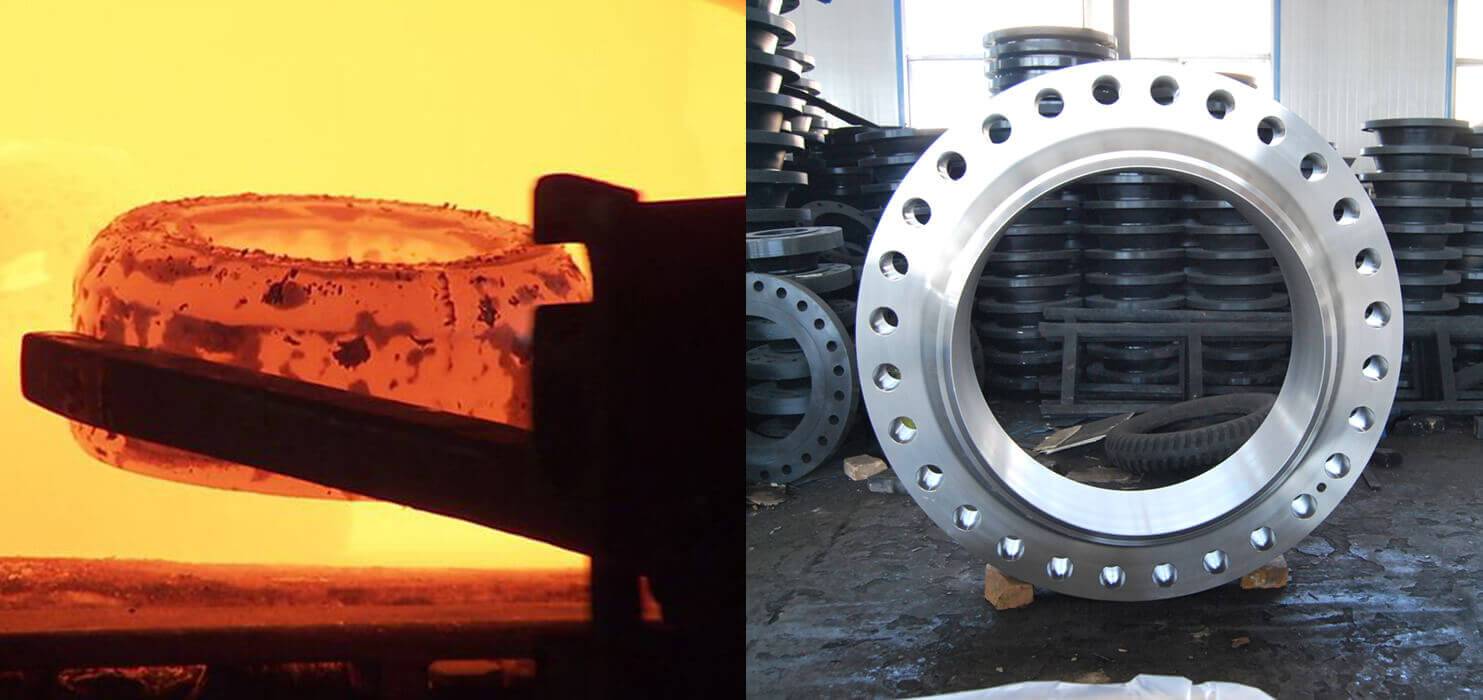

ASTM A182 F11 Flange is a type of pipe flange made of alloy steel. There are various uses for these flanges. ASTM A182 F11 Flanges have excellent weldability and corrosion resistance. Alloy Steel F11 Flanges and ASTM A182 F22 Flanges are used to connect the piping and its components in a piping system. ASTM A182 F11 Alloy Steel Flanges are widely used in welding applications. The pair is welded at both pipe ends and then welded or bolted together as a whole flange product. Alloy Steel ASTM A182 Grade F11 Flanges are often used for steam and other high-temperature fluids. They are also available in different shapes and sizes. Alloy Steel F11 Flanges and Alloy Steel ASTM A182 F22 Flanges are available in a variety of sizes, and they are often used in industries that are subjected to high pressures. They are made of carbon steel, manganese, and chromium, and their wall thickness varies depending on the pressure classes and diameters of the pipes.

With a product portfolio made of long-lasting piping components, Neo Impex Stainless Pvt. Ltd. provides a sustainable and high-quality alternative leading to growth in the business. We also offer our opinion on product selection, guiding you through the various options and selecting the best one for you. With us, you can be guaranteed the finest customer experience. We are a manufacturer, supplier, and exporter of Alloy Steel ASTM A182 F11 Flanges that have gained an integral positioning in several piping systems. Our range of Alloy Steel A182 F11 Orifice Flanges includes all types of conventional as well as customized Flanges compliant with ASTM A182, Specifications covering Alloy Steel Flanges for services at elevated temperatures.

Our Alloy Steel ASTM A182 F11 Blind Flanges which are also known as 'Chrome-Moly flanges', the Chromium and Molybdenum content that keep them away from corrosion and increase their toughness. The high creep strength and high-temperature resistance of ASTM A182 F11 Alloy Steel Threaded Flanges favor them to work in the petrochemical industry. Also, we offer a wide range of Alloy Steel F11 Flanges such as ASTM A182 F11 Slip On Flanges, Alloy Steel F11 Weld Neck Flanges, F11 Alloy Steel Socket Weld Flanges, A182 F11 Alloy Steel Blind Flanges, Alloy Steel F11 Orifice Flanges, A182 Alloy Steel F11 Spectacle Blind Flanges, A182 F11 Screwed / Threaded Flanges, Alloy Steel F11 Reducing Flanges, ASTM A182 F11 Alloy Steel Ring Type Joint Flanges (RTJ), etc.

What is an Alloy Steel ASTM A182 F11 Flange?

An ASME SA182 F11 Flanges is a type of pipe flange made from alloy steel and manufactured according to the ASTM A182 standard. The F11 designation indicates that the flange has a yield strength of at least 55,000 psi and a tensile strength of at least 60,000 psi. The flange is typically used in high-temperature, high-pressure applications such as power generation, oil and gas processing, and chemical processing.

What are the dimensions and pressure ratings of an alloy steel ASTM A182 F11 flange?

The dimensions of an Alloy Steel ASTM A182 F11 Flange can vary depending on the specific application. The pressure rating for this type of ASTM A182 F11 Flange is typically Class 1, which can handle a maximum pressure of 300 psi (2068 kPa) at temperatures up to 800°F (427°C).

What are the common applications of Alloy Steel ASTM A182 F11 Flanges?

Alloy Steel ASTM A182 F11 Flanges are commonly used in high-temperature, high-pressure applications such as:

Power generation: In power plants, the flanges are used in steam and water systems, as well as in the construction of boilers and heat exchangers.

Oil and gas processing: The flanges are used in the production, transportation and storage of oil and gas, including in pipelines, drilling rigs, and storage tanks.

Chemical processing: The flanges are used in the production of chemicals and petrochemicals, including in the construction of reactors, distillation columns, and storage tanks.

Specifications : ASTM A182 / ASME SA182

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2″ to 36″

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Forged and Plate Flanges

| Products | Size | |

| ASTM A182 Alloy Steel F11 Slip-On Flanges | ASTM A182 Alloy Steel F11 Threaded Flanges | Sizes 1/8″ – 36″ Raised Face or Flat Face |

| ASTM A182 Alloy Steel F11 Weld Neck Flanges | ASTM A182 Alloy Steel F11 Socket Weld Flanges | |

| ASTM A182 Alloy Steel F11 Blind Flanges | ASTM A182 Alloy Steel F11 Reducing Flanges | |

| ASTM A182 Alloy Steel F11 Lap Joint Flanges | ASTM A182 Alloy Steel F11 Plate Flanges | |

| ASTM A182 Alloy Steel F11 Orifice Flanges | ASTM A182 Alloy Steel F11 Forged Flanges | |

| ASTM A182 Alloy Steel F11 Ring Type Joint Flanges | ASTM A182 Alloy Steel F11 Square Flanges | |

Alloy Steel F11 Flange Standards / Types And Pressure Class :

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck Flange, Slip on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

ASTM A182 Alloy Steel F11 Equivalent

| Material | Name | Type Of | UNS Number | Forging Specification | Casting Specification Equivalent | DIN | Application |

|---|---|---|---|---|---|---|---|

| Alloy Steel & Chrome Moly | 1.1/4Cr-1/2Mo | K11572 | A182-F11 cl2 | A217-WC6 | 13CRM044 | 1.7335 | Up to 593ºC (1100ºF) |

| Grade | C | Mn | Si | S | P | Cr | Mo |

| A182 F11 | 0.05 - 0.15 | 0.3 - 0.6 | 0.5 - 1 | 0.03 | 0.03 | 1 - 1.5 | 0.044 - 0.65 |

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| A182 F11 | 205 | 415 | 20 |

Thickness Chart Of ASTM A182 Grade F11 Slip on Flanges

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

| 1/2" | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2" | 0.4 | 0.9 |

| 3/4" | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2" | 0.7 | 1.5 |

| 1" | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2" | 0.8 | 1.8 |

| 1-1/4" | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2" | 1.2 | 2.6 |

| 1-1/2" | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2" | 1.5 | 3.3 |

| 2" | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8" | 2.3 | 5.1 |

| 2-1/2" | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8" | 3.7 | 8.1 |

| 3" | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8" | 4.1 | 9 |

| 3-1/2" | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8" | 5.1 | 11.2 |

| 4" | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8" | 5.9 | 13 |

| 5" | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4" | 7 | 15.4 |

| 6" | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4" | 8.4 | 18.5 |

| 8" | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4" | 13 | 28.6 |

| 10" | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8" | 18 | 39.5 |

| 12" | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8" | 29 | 64 |

| 14" | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1" | 39 | 86 |

| 16" | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1" | 47 | 103 |

| 18" | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8" | 57 | 126 |

| 20" | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8" | 76 | 167 |

| 24" | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4" | 97 | 214 |

ASTM A182 F11 Flanges Pressure Rating Table

| ASTM A182 F11 Flanges | Pressure And Temperature Ratings | ||||||

| Temperature °F | Class 150 As Per ASME B16.5 | Class 300 As Per ASME B16.5 | Class 400 As Per ASME B16.5 | Class 600 As Per ASME B16.5 | Class 900 As Per ASME B16.5 | Class 1500 As Per ASME B16.5 | Class 2500 As Per ASME B16.5 |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

SA182 F11 Blind Flange Dimensional Tolerance

| ASTM A182 F11 Flanges | Tolerance Table | |

|---|---|---|

| A | O.D. (Outside Diameter) |

|

| D | Inside Diameter (I.D.) |

|

| B | Diameter of contact face |

|

| J | Diameter of hub at base |

|

| H | Diameter of hub at point of welding |

|

| P | Drilling |

|

| Eccentricity of bolt circle with respect to facing |

|

|

| C | Thickness |

|

| K | Length of hub |

|

| Alloy Steel F11 Flanges | Alloy Steel F11 EN 1092-1 Flanges |

| Alloy Steel F11 BS 4504 Flanges | Alloy Steel F11 Forged Flanges |

| Alloy Steel A182 F11 Flanges | Alloy Steel F11 Slip on Flanges |

| Alloy Steel F11 Flat Flange Suppliers | ANSI F11 Alloy Steel Blind Flange |

| Alloy Steel F11 Weld Neck Flanges Dealer | Alloy Steel F11 Socket weld Flanges Exporter |

| Alloy Steel F11 Long Weld Neck Flanges Stockholder | Steel ASTM A182 F11 Threaded Flanges Distributors |

| Alloy Steel ASTM A182 F11 Reducing Flanges | Alloy Steel F11 Ring Type Joint Flanges Manufacturer |

| Alloy Steel A182 F11 Orifice Flange | Alloy Steel 11/4 Cr-1/2Mo Spectacle Blind Flanges |

| Chrome Moly Alloy Steel F11 WNRF Flange | Alloy ASTM A182 F11 SORF Flanges |

| ANSI B16.5 Alloy Steel F11 RTJ Flanges | Alloy Steel F11 Screwed Flanges Stockist |

| ASTM A182 Alloy Steel F11 Lap Joint Flanges | ASME SA182 Alloy Steel F11 BLRF Flange |

| Alloy Steel F11 Raised Face Flanges | ASTM A182 F11 Alloy Steel Nipoflange |

| A182 Alloy Steel F11 Square Flanges | ASME SA182M Alloy Steel F11 SWRF Flange |

| Steel F11 Tongue & Groove Flanges | Chrome Moly Alloy Steel F11 Male & Female Flanges |

| Chrome Moly Alloy Steel F11 DIN Flanges | Alloy Steel F11 ASME B16.5 Flanges |

ASTM A182 F11 Pipe Flanges are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of ASTM A182 F11 Alloy Steel Flanges through a worldwide network of stock-keeping branches. These ASTM A182 F11 Alloy Flange is use in various industries like :

A Wide Range Of the Best Quality Alloy Steel ASTM A182 F11 Flanges, alloy steel f11 flanges specifications, alloy steel astm a182 f11 flange price list, alloy steel f11 flange price, alloy steel f11 flanges dimensions, a182 f11 chemical composition, a182 f11 equivalent, astm a182 f11 specification, astm a182 chemical composition, astm a182 f11 equivalent, chrome moly flanges, astm a182 f11 pdf, astm a182 f11 mechanical properties, sa182 f11, f11 material spec, astm a182 f11, astm a182 f11 class 1, astm a182 f11 class 3, astm a182 standard pdf, f11 material properties, sa182 flange, ASME/ ANSI, EN, DIN, AFNOR, AWWA, GOST, BS, JIS, AS, MSS, SA, UNI F11 Flanges, Ring Spacers, BS 10 Flanges, a182 f11 flanges manufacturer, 150# Alloy Steel F11 Flanges, 300# Alloy Steel F11 Flanges, 600# Alloy Steel F11 Flanges, 1500# Alloy Steel F11 Flanges, 2500# Alloy Steel F11 Flanges Manufacturer, Supplier in India.

MIDDLE EAST Saudi Arabia |

AFRICA Nigeria NORTH AMERICA Usa |

EUROPE Russia |

ASIA India SOUTH AMERICA Argentina |

We are renowned & most acclaimed Source, Stock, Distribution, Manufacturer, Suppliers, Stockholder, Traders, Wholesaler, Dealer, Distributor, Importer & Exporter, Fabricator, Stockist of ASTM A182 F11 Flanges in Alloy Steel.

For More Information About ASTM A182 F11 Alloy Steel Flange Please Call +91 22 6639 3943/44 or Send an Email to [email protected]