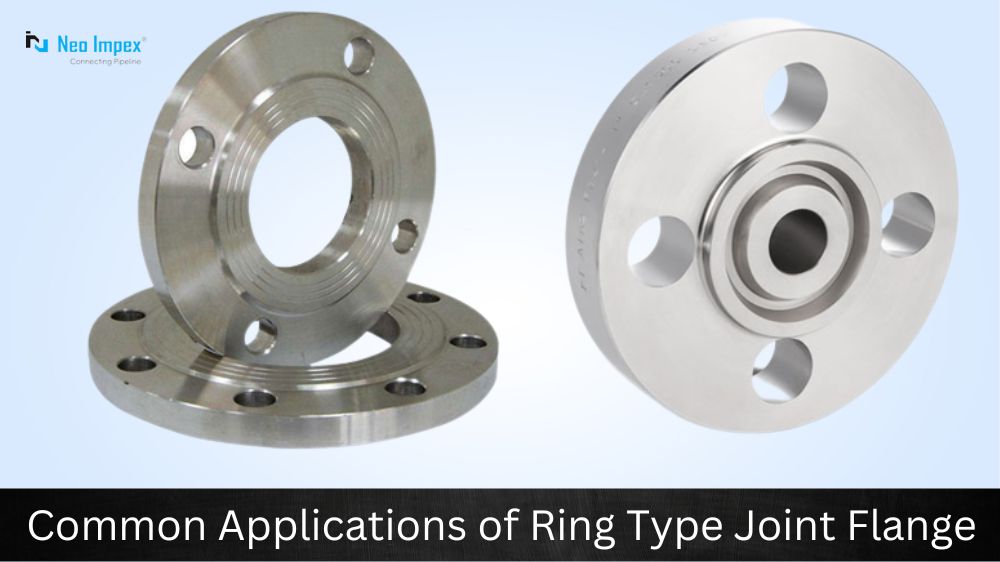

Ring Type Joint Flanges (RTJ) are specialized flanges that have end rings made of soft iron or steel to seal the flange joints. These flanges are often used in high-pressure and high-temperature applications in the oil and gas industry. But they’re not restricted to just that field – they’re versatile enough to be used in various applications, such as steam, chemical, and power plants. In this blog post, we’ll delve into the details of RTJ flanges, their types, and their common applications.

What are Ring Type Joint Flanges?

Ring Type Joint flanges are special flanges used to make a leak-proof connection in high-pressure systems. They have a metallic ring with a round or oval cross-section inserted into the groove of the two flange faces, providing an effective seal when tightened together. RTJ flanges can be used for vacuum and sub-zero temperature applications and up to 15,000 psi and higher pressures, making them incredibly durable and reliable for numerous industrial applications.

Applications of Ring Type Joint Flanges

Therefore, RTJ flanges can handle very high pressure and temperature and are more suited to extreme applications than other flanges. They have a trapezoidal cross-section that fits into an RTJ groove or recess on the flange face. This design ensures the flange stays connected even when subjected to high loads.

There are two types of RTJ flanges: oval and octagonal. The oval RTJ flange can absorb sealing loads that are less than its absolute rigidity, while the octagonal RTJ flange can handle sealing loads that exceed its rigidity. The flange face design and the types of materials used to manufacture them can vary depending on the application.

One of the most common applications of RTJ flanges is in the oil and gas industry. They are used in pipelines, drilling rigs, and refineries where high-pressure and high-temperature environments are integral to the operation. In addition to oil and gas, RTJ flanges can be used in steam boilers, chemical plants, and power generation plants.

One of the critical advantages of RTJ flanges is their ability to seal effectively against extreme pressure fluctuations, temperature variation, and corrosive environments. They can be customized to match the piping system’s dimensions and specifications, making them ideal for applications that require precision fitting.

Another advantage of using RTJ flanges is their reusability. Once installed and the flanges connect, they can be reused multiple times without losing their sealing capability or integrity. This feature is essential in the oil and gas industry, where periodic maintenance and inspection can affect production levels.

Properties of Ring Type Joint Flanges

- RTJ flanges are available in a wide variety of sizes and pressure classes.

- RTJ flanges can be manufactured using carbon steel, stainless steel, and nickel alloys.

- RTJ flanges are designed to seal under both pressure and vacuum conditions.

- RTJ flanges can be used in various applications, including oil and gas production, petrochemical processing, and power generation.

- RTJ flanges are available in both weld-neck and slip-on styles.

Conclusion:

Ring Type Joint Flanges are unique in handling extreme pressure and temperature fluctuations, making them perfect for use in harsh environments such as the oil and gas industry. They are adaptable to various applications, from steam boilers to chemical plants. Additionally, these flanges can be customized to match the piping system’s specifications, ensuring precise fitting. With their effective sealing capabilities against extreme pressure fluctuations, temperature variations, and corrosive environments, RTJ flanges are a reliable choice with proven track records.