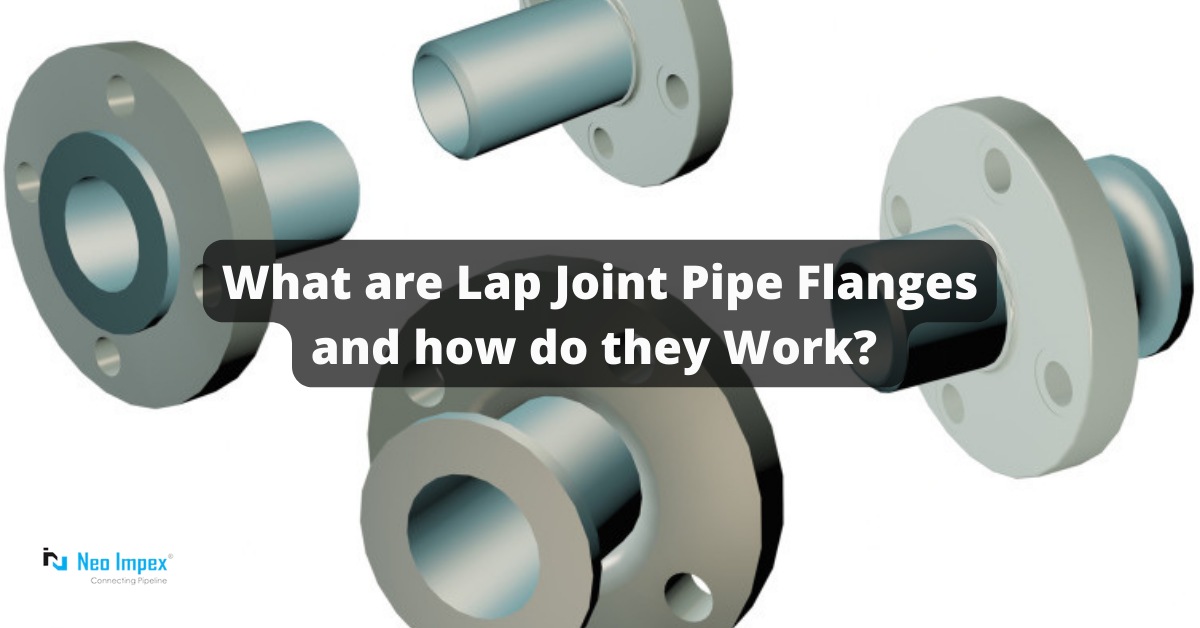

A Lap Joint Flange is a type of flange that is used to connect pipes with other equipment and fittings. It consists of a flat ring with an inner circle that slips over the pipe end. The ring has two flanges attached to it for bolting purposes, and thus it is also called a loose flange. Lap joint flanges are designed to save money on expensive materials used in pipe systems and simplify the assembly process.

The Lap Joint Pipe Flange is typically used in low-pressure systems. It is a cost-effective choice when flexibility in piping systems is necessary. The separate component design allows for easy equipment disassembly for maintenance or replacement. The Lap joint flange can also accommodate small misalignments between pipes and equipment. However, it should be noted that the lap joint flange is not recommended for high-pressure applications.

The Lap Joint Flange is installed on the end of a pipe, and a stub end is inserted in the flange. The stub end fits over the pipe but does not extend through the flange. The ASME B16.5 Lap Joint Flange uses a gasket to form a tight seal. The gasket is placed between the lap joint flange’s flat surface and the other flange’s flat surface. This arrangement allows for easy alignment adjustments and reduces the crushing of the gasket material.

Lap Joint Flanges are used in various industries, including chemical, petrochemical, construction, and food and beverage. Lap joint flanges come in different materials, such as carbon steel, stainless steel, nickel alloys, and titanium. Choosing the right material for the flange depends on the type and temperature of fluid or gas that the piping will carry.

Conclusion:

Lap Joint Flanges are an essential component of piping systems and are designed to securely connect pipes to other equipment and fittings. They are cost-effective and can accommodate small misalignments between pipes and equipment. These flanges are straightforward in design, and working with them does not require a high level of experience. Lap joint flanges are designed for low-pressure applications and are not used in high-pressure systems.