Butt weld fittings are crucial in modern piping systems, providing durable, leak-proof, and seamless connections ideal for high-performance operations. Extensively used in oil and gas, chemical plants, power generation, and shipbuilding, these fittings ensure reliability under pressure. In this blog, we’ll start by explaining what a butt joint weld is and the different types commonly used. We’ll then cover standard preparation procedures, including edge preparation, cleaning, and alignment, which are essential for achieving quality welds. You’ll discover various welding methods such as TIG, MIG, and arc welding, each suited to specific applications. We’ll also explore the common uses of butt welds in industrial systems, their key advantages like strength, corrosion resistance, and minimal flow restriction, as well as drawbacks including skilled labor needs and preparation time. Whether designing or maintaining a system, this guide helps professionals make informed decisions.

What is a Butt Joint Weld?

A butt joint weld is one of the easiest and most prevalent welds. It’s created when two metal pieces are placed in the same plane and welded at their edges. This weld is particularly favored in pipeline construction and structural fabrication where long pipe or sheet metal runs must be joined seamlessly.

The butt joint provides full penetration welding, which is strong and can be used in high-pressure and high-temperature conditions.

Types of Butt Weld Joints

There are a number of butt weld joints and each is chosen according to the requirement of the project, material thickness, and position of welding:

- Square Butt Joint

Used for thinner materials, this joint has square edges and requires minimal preparation. - Single V Butt Joint

Typically applied to thicker material, it entails beveling the edges of both pieces in a “V” shape. - Double V Butt Joint

Like the single V, but both sides of the joint are beveled. This is applied when welding on both sides can be done. - Single Bevel Butt Joint

Only one of the two joining edges is beveled. This joint is used when access is limited on one side. - Double Bevel Butt Joint

Both the edges are beveled and welding is performed from both sides to provide full penetration. - Standard Butt Weld Preparation Process

Proper preparation is essential for obtaining a good and clean butt weld. Preparation is usually carried out in the following steps: - Material Cleaning

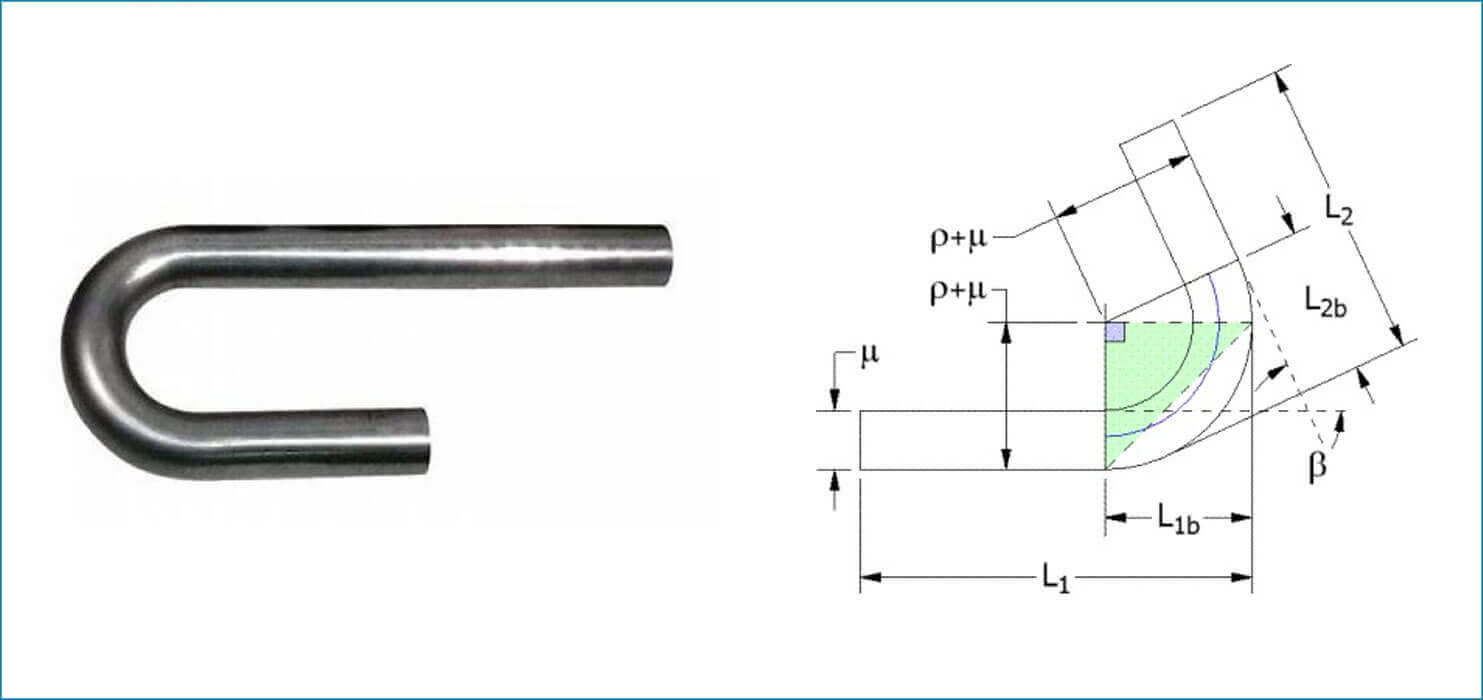

Surfaces should be clean from rust, oil, paint or any other impurities that would influence weld quality. - Edge Preparation

Depending on the type of joint, edges are cut, beveled, or machined to the correct shape. - Alignment and Fit-up

The pieces to be welded are properly aligned using clamps or fixtures. Proper spacing (root gap) is maintained. - Preheating (if required)

For thicker materials or high-carbon steels, preheating may be necessary to avoid cracking. - Tack Welding

Temporary welds are placed at intervals to hold the joint in position before the final weld is performed.

Butt Joint Welding Techniques

Several welding techniques can be applied to butt joints, each chosen based on factors such as material type, thickness, project requirements, and environment.

- Shielded Metal Arc Welding (SMAW)

Also referred to as stick welding, SMAW is a process of manual welding where an electric current creates an arc between the covered metal electrode and the base metal. It is extremely versatile, portable and also suitable for outdoor conditions and on rusty or dirty surfaces. This method is commonly utilized in construction, shipbuilding, and repair work because of its tough nature. - Gas Tungsten Arc Welding (GTAW/TIG)

GTAW or TIG welding uses a non-consumable tungsten electrode and an inert gas (typically argon) to protect the weld area from contamination. It produces precise, high-quality welds, especially on thin materials and non-ferrous metals like aluminum and copper alloys. This method is often used in critical applications like aerospace, food processing equipment and piping systems where clean, defect-free welds are essential. - Gas Metal Arc Welding (GMAW/MIG)

MIG welding is a semi-automatic process in which a continuously fed wire electrode is melted and joined together with the base materials. It is simple to learn and has a high speed of welding, making it suitable for manufacturing, auto repair and light fabrication work. GMAW has good control and cleaner welds than SMAW, but might not do so well in dirty or windy environments. - Submerged Arc Welding (SAW)

SAW is the process of creating an arc between the continuously fed wire electrode, and the workpiece under a granular flux blanket. It provides deep penetration of welds and high deposition rates, thus suitable for welding thick steel sections as well as long seams in heavy machinery, pipes, and pressure vessels. Due to its low spatter and high efficiency, it is perfect for automated large-scale fabrication systems. - Flux-Cored Arc Welding (FCAW)

FCAW is similar to MIG welding but uses a tubular wire filled with flux, which creates a shielding gas when heated. This process is excellent for welding outdoors or in windy conditions and provides deep weld penetration. It is widely used in structural steelwork, shipbuilding, and heavy fabrication due to its speed, flexibility and ability to handle dirty or painted metals.

Applications of Butt Joint Welding

Butt weld fittings play a crucial role in numerous industries because they are strong and, enduring:

- Oil & Gas Industry

Critical in the manufacture of pipelines employed to carry crude oil, natural gas, and other petroleum products. The strength and integrity of butt weld joints ensure safe and efficient flow over long distances even under high pressure, and temperature conditions. - Power Plants

Utilized with great frequency in high-pressure uses such as boilers, turbines, heat exchangers and steam pipe lines. Butt weld joints provide the required strength and durability to withstand harsh operating conditions. - Chemical & Petrochemical Industries

Appropriate for processes handling harsh chemicals and high-temperature fluids. Seamless butt welds minimize the possibility of leaks and corrosion thus ensuring process integrity and resilience. - Shipbuilding

Utilized widely to join big metal plates and structural pieces. Butt welding makes strong, flush welds with added strength and watertightness for ships and boats. - Water & Wastewater Treatment Plants

Provide leak-resistant and strong welds necessary in carrying treated water and untreated water. The clean internal surface of the weld reduces flow resistance and prevents deposition. - Food & Beverage Industry

Stainless steel butt weld fittings are the choice in hygienic processing equipment. They form smooth, crevice-free welds that are simple to clean and maintain conforming to high sanitary requirements.

Advantages of Butt Joint Welding

- Strong and Durable: Provides full penetration and high-strength welds capable of handling high pressure and temperature.

- Smooth Internal Surface: Especially important in pipelines to reduce turbulence and improve flow.

- Cost-Effective: Requires fewer fittings and joints compared to alternative methods like flanged connections.

- Neat Appearance: After proper finishing, the joint looks clean and professional, suitable for exposed piping.

- Versatility: Can be used with various welding techniques and for different materials.

Disadvantages of Butt Joint Welding

- Skill-Dependent: Requires skilled welders to ensure high-quality joints, especially for critical applications.

- Preparation Time: Edge preparation, alignment, and setup can be time-consuming.

- Inspection & Testing Required: Non-destructive testing (NDT), such as X-rays or ultrasonic testing, may be necessary to verify weld integrity.

- Difficult in Confined Spaces: Access can be limited, especially in retrofit jobs or compact areas.

Conclusion

Butt Joint Welding is a pillar in the piping and fabrication industry because of its reliability, strength, and smooth appearance. Knowing the types of butt weld joints, preparation methods, and welding processes is vital for experts who want to ensure quality and safety. Though it has drawbacks in terms of skill needs and preparation time, the advantages in terms of strength and efficiency make it a significant welding process. With proper technique and utmost care, butt weld fittings can be a long lasting solution in a vast array of industries.