Stainless steel (SS) butt weld fittings are essential components in piping systems used across industries such as oil and gas, chemical processing, and water treatment. Known for their strength, corrosion resistance, and ability to form leak-proof connections, these fittings join two pipe sections through welded joints to ensure durability and safety. In this blog, we’ll take a closer look at the various types of SS butt weld fittings commonly used, explain how their weight is calculated for accurate cost estimation and handling, and explore the different types of welding joints that provide strong, reliable pipe connections. Whether you’re involved in system design, procurement, or installation, understanding these factors will help you make informed decisions and optimize your piping projects.

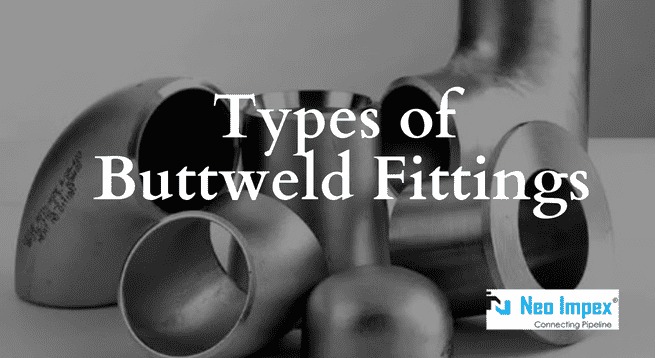

Types of SS Butt Weld Fittings

Stainless steel butt weld fittings come in many forms and designs to suit the needs of different piping systems. Every fitting performs a special purpose, providing smooth flow, direction change or size change in the piping. The most used types are listed below:

Elbows

Elbows are meant to alter the flow direction in a piping system. They come in various angles usually 45°, 90° and 180°, permitting smooth directional alteration without flow disruptions. Elbows play crucial roles in applications where space or layout complexity demands sharp or sweeping turns.

Tees

A tee fitting provides for branching out from the main pipeline. It has one inlet and two outlets, oriented at a 90-degree angle having a “T” shape. Tees proven useful in diverting flow or in making junctions in pipeline networks.

Reducers

These are fittings that are utilized to join pipes of varying diameters ensuring a smooth change and flow efficiency. They are available in two primary forms:

- Concentric reducers, with a symmetrical cone shape and utilized when the pipeline is in alignment.

- Eccentric reducers are utilized when the pipeline alignment must be retained on one side, particularly in horizontal pipelines.

Caps

Caps seal the pipe’s end where the flow is cut off. Caps find their application in temporary closure for replacement or maintenance and also as a permanent end in a pipeline system.

Crosses

Like tees, crosses also contain four openings, one inlet and three outlets or the reverse – in a cross pattern. These are usually employed in intricate piping systems in which various pipelines intersect each other.

Couplings

Couplings are used to connect two straight sections of pipe. They come in:

- Full couplings, which connect pipes of the same diameter.

- Half couplings, which are used for branching from a pipe or connecting a smaller pipe to a larger one.

Each of these fittings plays a critical role in constructing a durable and efficient stainless steel piping system. By choosing the correct size and type, engineers and installers are able to guarantee optimal system integrity, and flow performance.

Factors Affecting the Weight of SS Butt Weld Fittings

Several factors determins the weight of SS butt weld fittings:

- Size

Bigger diameter pipes and fittings will weigh more as they require more material to manufacture. - Material Thickness

The heavier the stainless steel, the heavier the fitting. High-pressure applications involve thicker material, and this contributes to the weight. - Type of Fitting

Different fittings vary in design and complexity, and some (such as crosses) require more material than others (such as elbows). - Grade of Stainless Steel

The particular alloy of stainless steel utilized (e.g., 304, 316 or duplex stainless steel) may also influence the weight. More premium steels are denser resulting in heavier fittings.

For instance, a big SS elbow fitting (e.g., 8 inches in diameter) can weigh several kilograms, whereas a small elbow (1 inch in diameter) can weigh only a fraction of that. The manufacturers usually offer detailed weight charts for every type of fitting to assist in project planning.

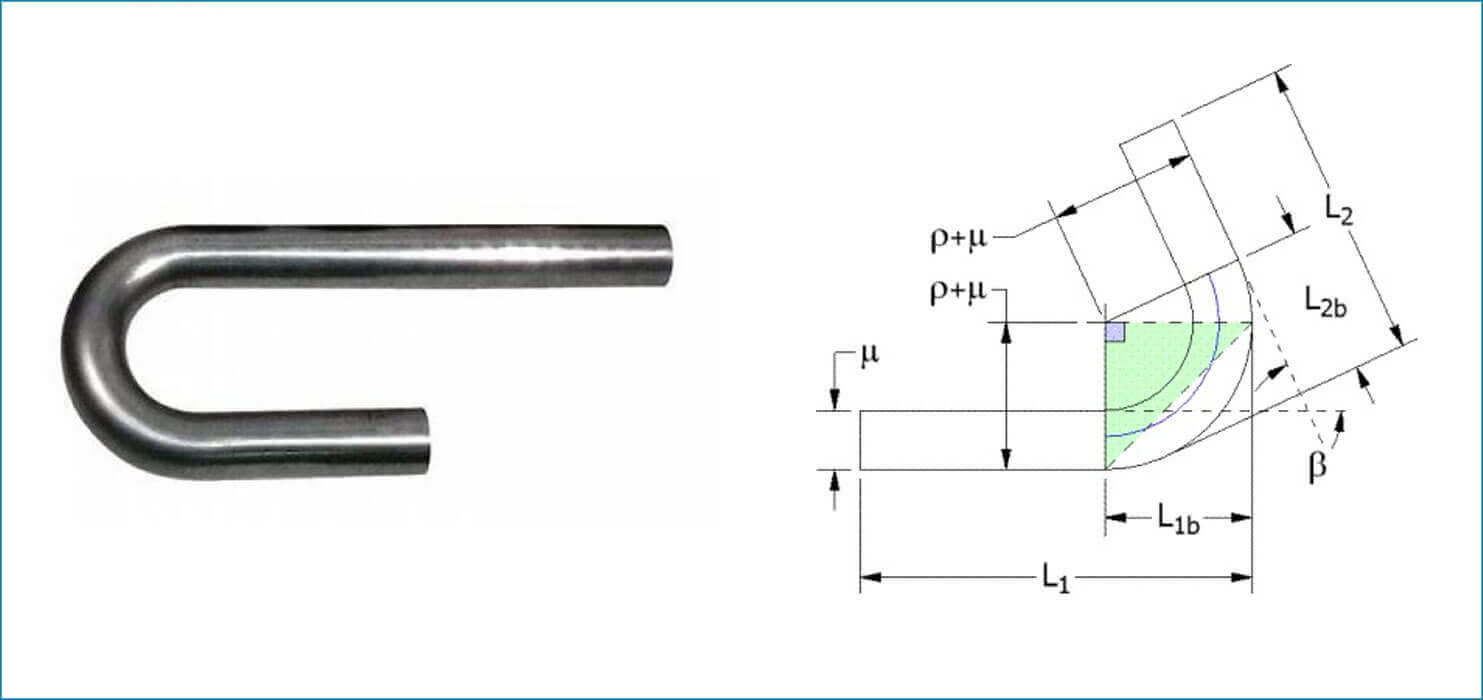

Types of Welding Joints

Welding joints are essential to understanding how SS butt weld fittings are used in the piping system. They refer to the way two pieces of metal are connected during the welding process. Here are the most common types:

- Butt Joint

It is the most popular type of welding joint applied to butt weld fittings. The edges of the two pipes are aligned and joined together to create a straight line. This joint is usually applied in piping connection between the pipes in a pipeline. - Corner Joint

In this joint, two pieces of metal meet at a right angle, typically used when joining pipes or plates in a corner. - T-Joint

The metal pieces are welded at a right angle to create a “T” shape. It is mostly applied in cases where pipes must branch out from the main pipeline. - Edge Joint

This is applied when two metal pieces are welded together along their edges. This joint is prevalent in sheet metal usage.

Each welding joint affects how the pipe or fitting is installed and how it carries the pressure and stress of the piping system. The strength of the joint is determined by the welding method used, the materials, and the type of joint chosen.

Conclusion

When working with SS butt weld fittings, understanding their weight and various types of welding joints is important to ensure proper installation and safety. The weight of the fittings varies based on size, material thickness, type of fitting, and grade of stainless steel. On the other hand, the right welding joint selection guarantees the strength and reliability of the piping system.

Whether you’re working on a small-scale installation or a large industrial project, knowing the weight and properties of SS butt weld fittings, as well as the appropriate welding joints, will help you make informed decisions for optimal performance and cost-effectiveness.