-

Call Us

-

Email Us

Call Us

Email Us

Table Of Content

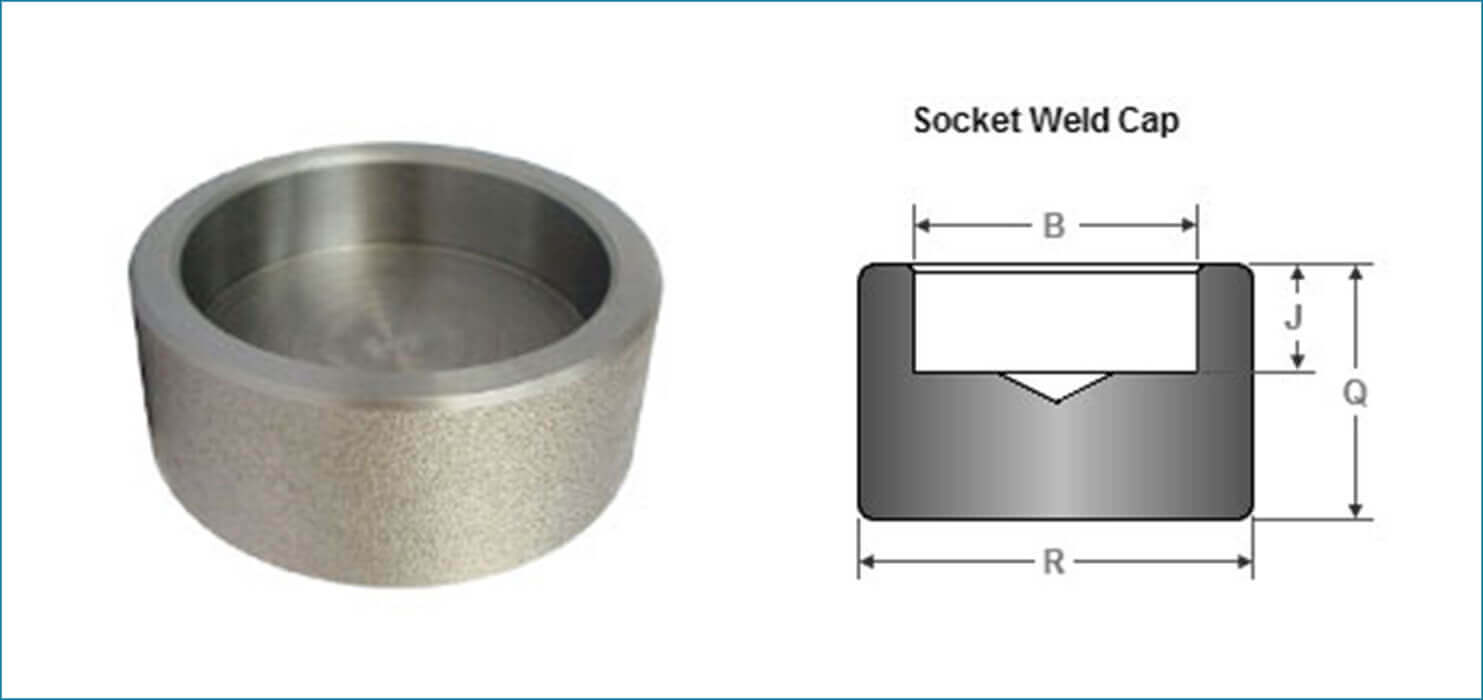

Neo Impex Stainless Pvt. Ltd. is a manufacturer, distributor and supplier of Socket Weld Caps. It is an innovative ISO certified company that uses responsive services to entice the customers. A Socket Weld fitting is a kind of pipe fitting which is inserted into a recessed valve, fitting or flange. A Stainless Steel Socket Weld Cap is a type of pipe fitting, usually liquid or gas tight which covers the end of a pipe to stop the flow. The functions of a cap are similar to a plug. They have excellent corrosion resistance. They are mainly used for small pipe diameters. This vast variety is provided to the clients by the renowned stockist and exporter, Neo Impex Stainless Pvt. Ltd., in multiple sizes, as per the customised requirements. They are offered to clients with the option of customising the size as per the individual purchasers.

What is a B16.11 forged socket weld pipe cap?

B16.11 forged socket weld pipe cap is a type of pipe fitting used to seal the end of a socket weld pipe. It is forged from high-quality materials such as carbon steel, stainless steel, or alloy steel & features a socket weld connection for easy installation. The cap is designed to provide a leak-tight seal, protecting the pipe and its contents from contamination or damage.

What are the advantages of using B16.11 forged socket weld pipe caps?

The Advantages of Using B16.11 Forged Socket Weld Pipe Caps include strong and secure connections, prevention of leaks and other issues, durability, and suitability for use in demanding industrial applications. They are also available in various sizes and materials, making them versatile and suitable for different pipeline systems.

How are B16.11 forged socket weld pipe caps installed?

B16.11 Forged Socket Weld Pipe caps are installed by first preparing the end of the pipe by cleaning and deburring it. The cap is then inserted Into the pipe, and the pipe and cap are welded together using a socket weld joint. The joint is heated using a welding torch until the metal becomes molten and fuses. The joint is then allowed to cool and solidify, creating a strong, leak-tight connection between the pipe and cap.

Dimensions : ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799

Size : 1/8" NB TO 4" NB

Pressure Class : 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

Form : Caps, Pipe Caps, End Pipe Caps.

Stainless Steel Forged Socket Weld Pipe Cap :

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Socket Weld Pipe Cap :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Socket Weld Pipe Cap :

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Socket Weld Pipe Cap :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Socket Weld Pipe Cap : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 45/10) , C 71500 ( CU -NI- 70/30)

Nickel Alloy Forged Socket Weld Pipe Cap :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

| Forged Socket weld Pipe Cap | Socket weld Pipe Cap |

| 150 lb. Socket Weld Fittings Pipe Cap | Socket weld Forged Cap |

| ASME B16.11 Forged Socket weld Pipe Cap | Forged Pipe Caps 3000LB Socket Weld |

| Stainless Steel Pipe Cap Suppliers | SS Forged Socket weld Pipe Cap |

| ANSI B16.11 Forged Socket weld Pipe Cap Dealer | BS 3799 Forged Pipe Caps Exporter |

| Forged Socket weld Pipe Cap Stockholder | Socket weld Forged Pipe Cap Distributors |

| Carbon Steel Socket weld Pipe Cap | High Quality Socket weld Pipe Cap Manufacturer |

| ASTM A182 Socket weld Stainless Steel Pipe Cap | Duplex Steel Socket weld Pipe Cap |

| Super Duplex Steel End Pipe Caps | Copper Nickel Socket weld Pipe Cap |

| High Nickel Alloy Forged Socket weld Pipe Cap | Hastelloy Socket weld Pipe Cap Stockist |

| Titanium Forged Socket weld Pipe Cap | Inconel Socket weld Pipe Caps |

ASME B16.11 Socket weld Pipe Cap are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Forged Socket weld Pipe Cap through a worldwide network of stock-keeping branches. These Forged Socket weld Pipe Cap is use in various industries like :

MIDDLE EAST Saudi Arabia |

AFRICA Nigeria NORTH AMERICA Usa |

EUROPE Russia |

ASIA India SOUTH AMERICA Argentina |

We are renowned & most acclaimed Source, Stock, Distribution, Manufacturer, Suppliers, Stockholder, Traders, Wholesaler, Dealer, Distributor, Importer & Exporter, Fabricator, Stockist of Forged Socket weld Pipe Cap in Stainless Steel.

For More Information About Socket weld Pipe Cap Please Call +91 22 6639 3943/44 or Send an Email to [email protected]